Efficient and reliable bumper cover replacement relies on original equipment manufacturer (OEM) parts, rigorously tested for quality and compatibility. Technicians use specialized tools and knowledge to ensure precise installation, enhancing safety and preserving vehicle value. This guide outlines each step of the process, from initial inspection to final installation, emphasizing meticulous attention to detail for flawless cosmetic repair and improved collision safety.

Technicians play a pivotal role in ensuring the quality and safety of vehicle repairs, especially during crucial tasks like bumper cover replacement. This article delves into the significance of using Original Equipment Manufacturer (OEM) parts for bumper covers. We explore the benefits of OEM parts, highlighting their impact on performance, durability, and safety. Additionally, we outline the step-by-step process technicians follow to ensure a seamless and effective bumper cover replacement.

- Understanding OEM Parts: Benefits for Bumper Cover Replacement

- The Role of Technicians in Ensuring Quality and Safety

- Step-by-Step Guide: Effective Bumper Cover Replacement Process

Understanding OEM Parts: Benefits for Bumper Cover Replacement

Understanding OEM parts is key when it comes to efficient and reliable bumper cover replacement. OEM stands for Original Equipment Manufacturer, referring to the specific parts that were designed and produced by the vehicle manufacturer. Using OEM parts for bumper cover replacement offers numerous advantages. Firstly, they are engineered to perfectly fit your car model, ensuring a seamless installation without any modifications needed. This precision fitting also guarantees optimal performance during impact absorption in case of future car collisions, enhancing overall safety.

Additionally, OEM parts provide peace of mind as they undergo rigorous quality control checks, meeting the manufacturer’s strict standards for both functionality and durability. Incorporating these parts into auto body repairs ensures that your vehicle retains its original specifications, preserving its value and aesthetic appeal over time. Moreover, they can facilitate smoother auto maintenance routines by aligning with the recommended replacement intervals specified by the vehicle producer.

The Role of Technicians in Ensuring Quality and Safety

In the intricate process of bumper cover replacement, technicians play a pivotal role in maintaining quality and safety standards. Their expertise is instrumental in ensuring that each component, from the precise measurement of the frame straightening to the meticulous installation of OEM (Original Equipment Manufacturer) parts, aligns perfectly with the vehicle’s specifications. Technicians employ advanced tools and techniques to perform intricate repairs, including detailed frame straightening when necessary, guaranteeing both structural integrity and a seamless fit for the new bumper cover.

Moreover, these professionals prioritize customer safety by adhering to strict quality control measures throughout the bumper cover replacement process. They meticulously inspect every part, ensuring it is in pristine condition and compatible with the specific make and model of the vehicle. This meticulous approach, combined with their extensive training and experience in automotive body shops like Mercedes Benz collision repair centers, results in superior repairs that not only restore the vehicle’s aesthetic appeal but also maintain its safety features.

Step-by-Step Guide: Effective Bumper Cover Replacement Process

Step-by-Step Guide: Effective Bumper Cover Replacement Process

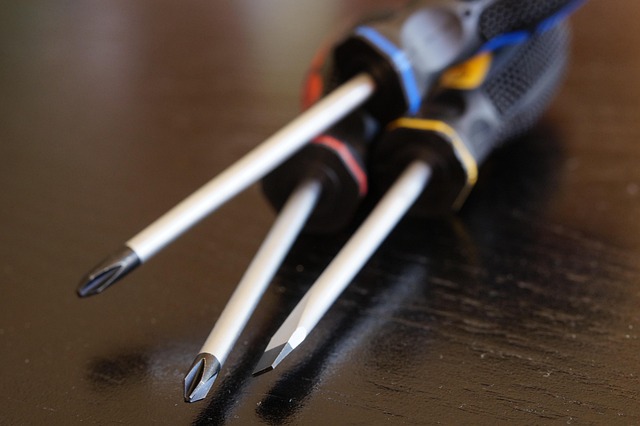

Bumper cover replacement is a common task in auto repair shops and car body shops, often necessitated by minor fender benders or cosmetic damage. The process begins with a thorough inspection of the existing bumper cover to identify any cracks, dents, or damages. Technicians then gather the necessary tools and OEM (Original Equipment Manufacturer) parts, ensuring they are compatible with the vehicle model. Next, the old bumper cover is carefully removed, often involving the disconnection of lights, sensors, and other components.

Once the old cover is off, the new OEM part is fitted precisely, aligning it with the car’s frame and ensuring all hardware is secured properly. After double-checking the fitment, technicians reattach any disconnected components and clean up the area around the bumper. This meticulous process guarantees a seamless finish that not only restores the vehicle’s aesthetic appeal but also reinforces its overall safety in the event of future collisions.

When it comes to bumper cover replacement, technicians play a pivotal role in ensuring quality and safety by utilizing Original Equipment Manufacturer (OEM) parts. These genuine components offer numerous benefits, including superior fitment, enhanced durability, and optimal performance. By following a meticulous step-by-step process, technicians can efficiently restore the vehicle’s aesthetic appeal and structural integrity. In today’s market, prioritizing OEM parts for bumper cover replacement is a surefire way to guarantee a long-lasting fix that keeps your vehicle looking its best on the road.